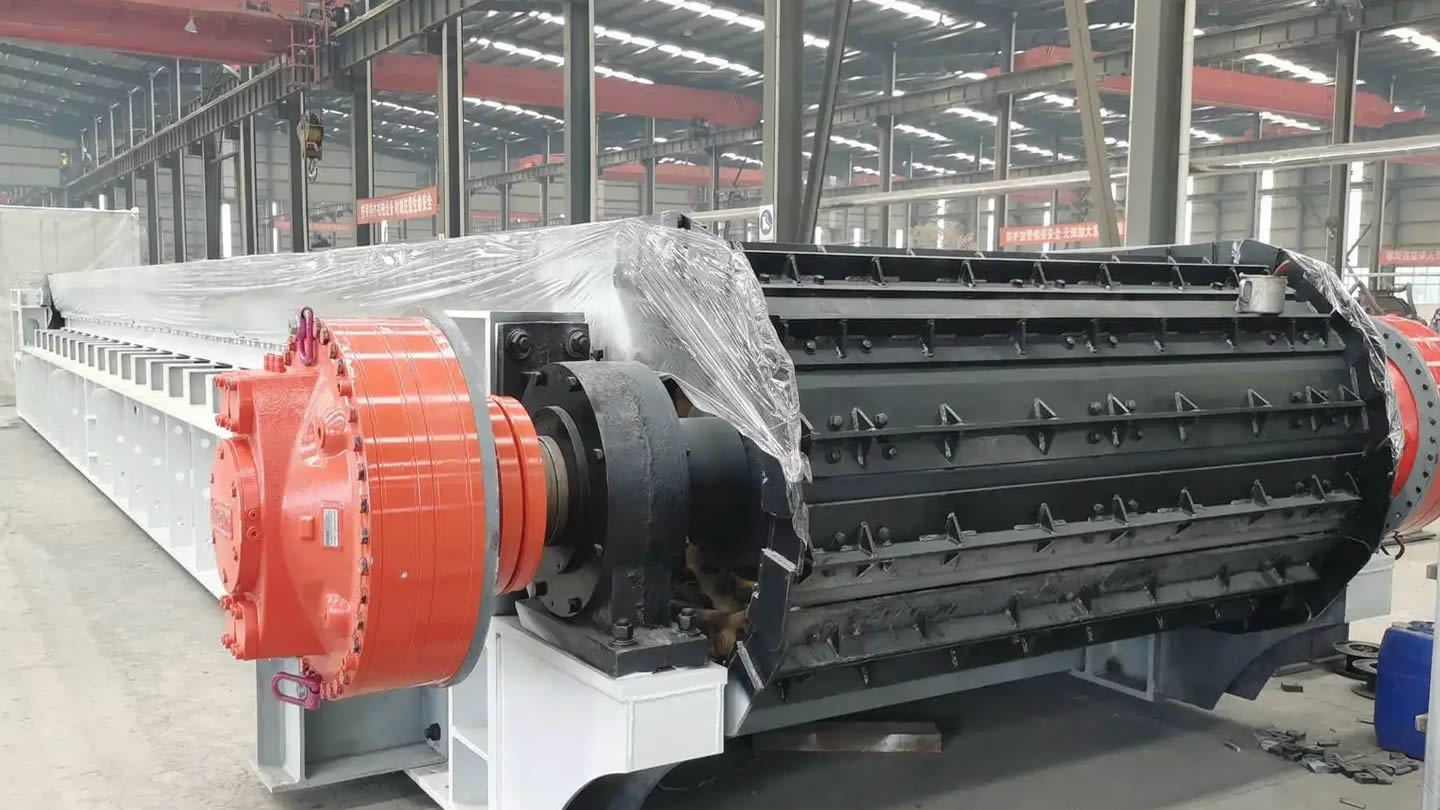

Apron Feeders are a reliable feeding method used to feed a wide variety of applications. It is suitable for heavy loads and high impact loads from large coarse materials directly dumped. Apron feeders adopt variable frequency speed adjustment and enable intelligent interlocking with downstream equipment, significantly improving production efficiency and reducing operational costs for customers.

Apron Feeders mainly consist of drive units, sprockets, chains & rollers, apron plates, support frame, tail tension device etc.

When the head sprocket is driven, the traction chain in the apron plate chain device meshes with the sprocket to drive the entire apron plates to move along the longitudinal center-line and the roller travels along the track fixed on the frame,thereby completing work.

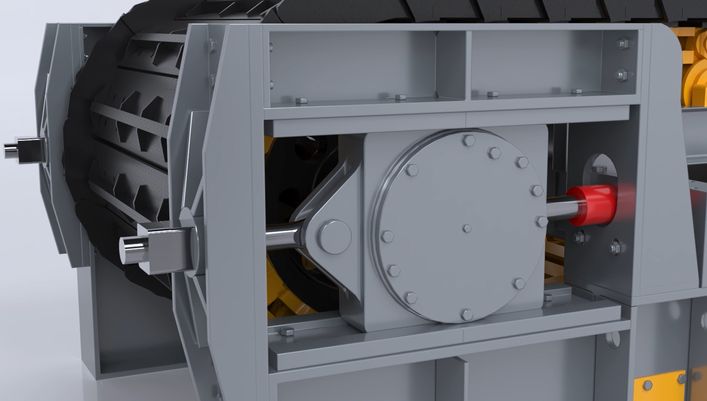

Drive Units

Drive Units utilize an AC variable frequency drive system that integrates software with electronic and mechanical systems to provide precise conveyor speed control and overload protection. The main components of drive units can choose SIEMENS, ABB, SEW, FLENDER and other well-known domestic and foreign brands of motor and gearbox, to provide stable and continuous kinetic energy output, with high efficiency, low noise and vibration etc.

Sprocket

Cast manganese sprockets bolted to heavy steel hubs keyed to oversized front drive shaft. The segmental sprockets can be replaced in a very short time without needing to dismantle or remove other parts of the apron feeder.

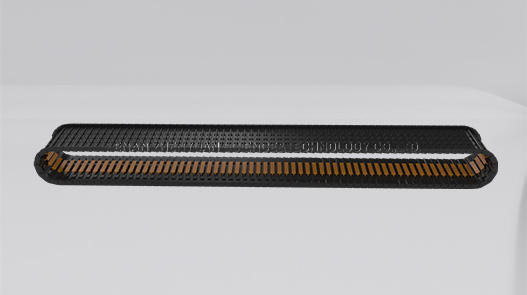

Apron Plates

The apron plates bolted to the chain with high strength bolts and nuts, which can be replaced individually in situ without disturbing the rest of apron feeder.

According to different working conditions, apron feeder can choose heavy duty cast manganese steel or

welded construction with ribbed reinforcements, which is suited for materials with high load and high impact conditions.

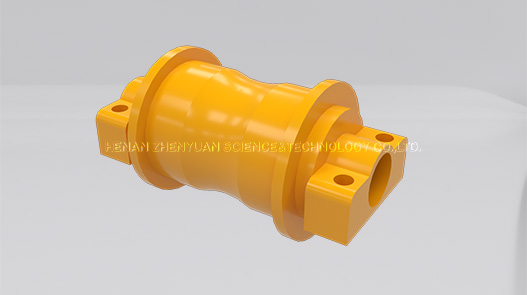

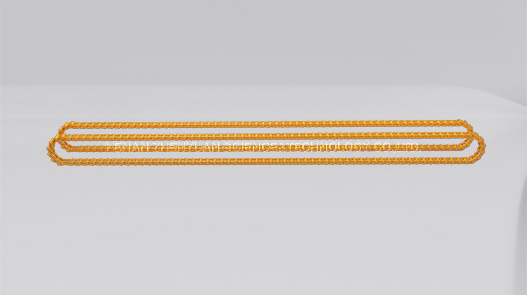

Chains & Rollers

The chain uses an off the shelf dozers chain(track chain), which is characterized by small pitch error,

smooth movement, high strength, large pulling force, and the chain has a self-lubricating device and

a sealing device. The rollers are designed as a standard tractor rollers with sealed and lifetime

lubricated bearings, mounted on the main feeder frame. The rollers has suitably spaced to provide

adequate support for the chain assembly.

The chains & rollers can use world famous brands according to customer needs, such as Caterpillar,- Komatsu, and Shantui.

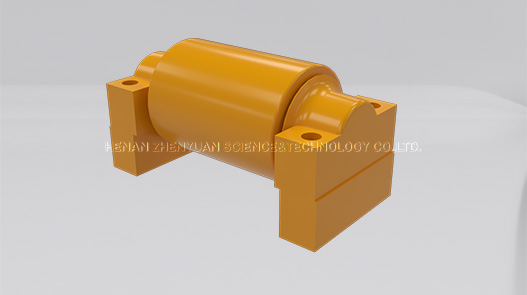

Tail Tension Device

The tension device is used to tighten and adjust the horizontal position of the chain to ensure that the

chain tightness is moderate and make it run smoothly.

When the apron plates are suddenly impacted by the material, the composite spring can play a buffer role to protect the apron plates and other components from damage.

FEATURES

- High Impact Resistance

- Flexible Layout

- With Self-lubricating System

- With Intelligent Control System

- Easy Installation

- Widely Applications

- Uniform Feeding

- Convenient Maintenance

- Large Capacity

- Heavy-load Starting Capability

- Low Operation Cost

- Long Service Life

KEY BENEFITS

Rugged steel support frame with impact rails to limit apron plates deflection, thus eliminating permanent bending of the apron feeders. And it can withstand all loading conditions during starting and operation.

Apron feeders can be installed in both horizontal and inclined applications. The high inclination also allows to build compact installations and reduce the length of apron feeder and height of civil foundation, thus keeping the equipment and construction costs low.

Apron feeder with frequency converter, and it can change the speed of main motor, thereby changing the chain speed, which can achieve the purpose of adjusting the handling capacity of apron feeder.

The core components of apron feeder have a long service life and minimal maintenance, which reduces downtime and increases productivity, thereby increasing profitability for customers.

ADEQUATE SPARE PARTS

We have a perfect warehouse management system and spare parts reserve, which can quickly provide spare parts when customers need them, reduce eguipment downtime and save operating costs.