Mineral sizer is a modern approach to crushing that uses shear force and tensile force between the teeth rollers to crush materials, which is the best choice for handling hard, wet, sticky materials.

Mineral sizer is a type of graded crushing equipment which can provide primary, secondary and tertiary crushing operations for many kinds of mineral.

Mineral sizer is mainly composed of drive unit, teeth roller, ynchromesh gear, housing, base frame, lubrication device, running gear and so on.

HOW MINERAL SIZER WORKS

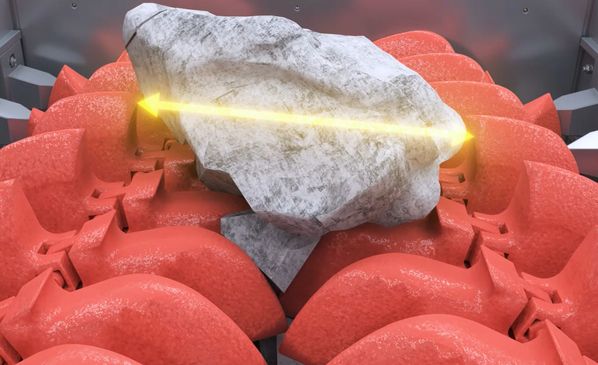

Mineral Sizer has two inwardly rotating teeth rollers with replaceable crushing teeth head. The most suitable feeding method is by apron feeder or screening equipment, which conveys the material at a uniform rate and distributes it evenly over the teeth rolers.

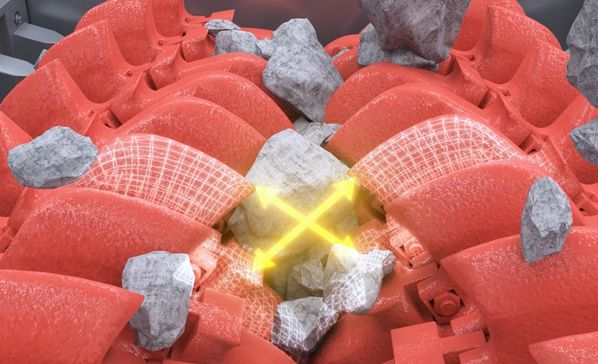

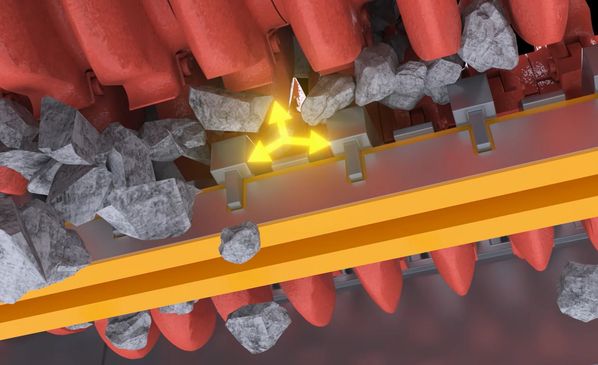

The mineral is gripped by the leading faces of opposed rotor teeth, and to be subjected to stress under the concentrated load of the rotor teeth. The stress breaks minerals along with their natural texture.

The mineral is broken in tension by being subjected to a three point loading between the front teeth faces on one rotor and rear teeth faces on the other rotor.

The mineral that has not been fully broken can be further broken by the rotor teeth and fixed teeth of the breaker bar to ensure the 3d dimension requirements of the discharging material.

STRUCTURES

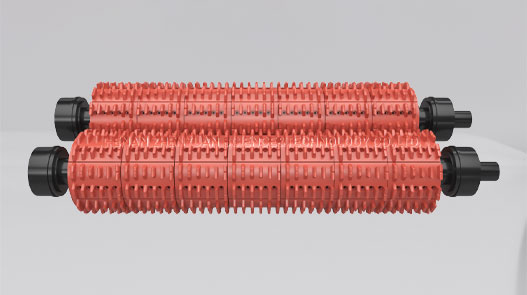

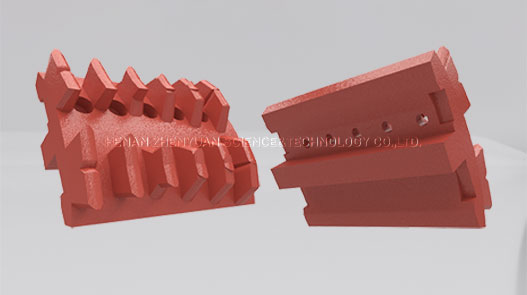

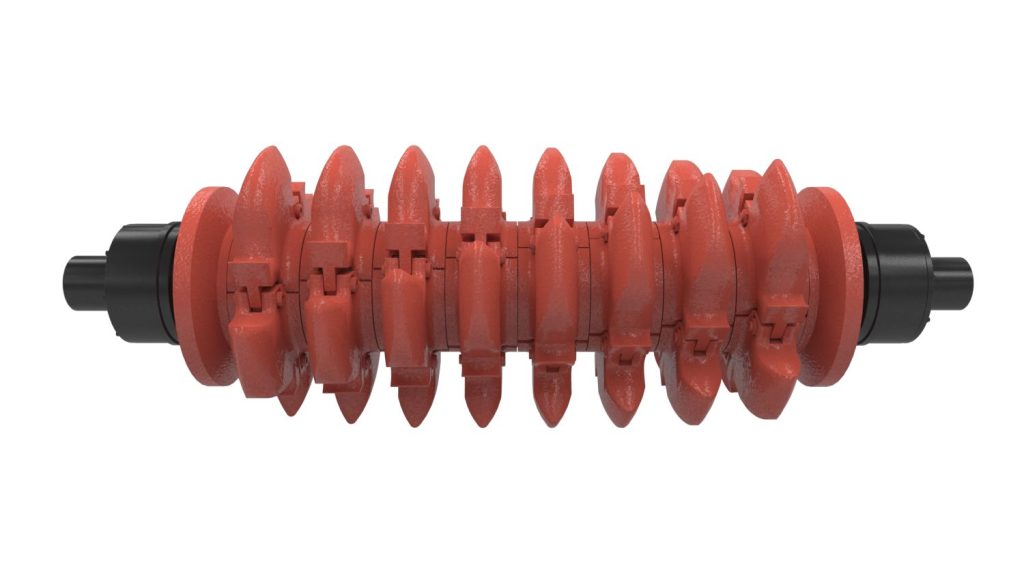

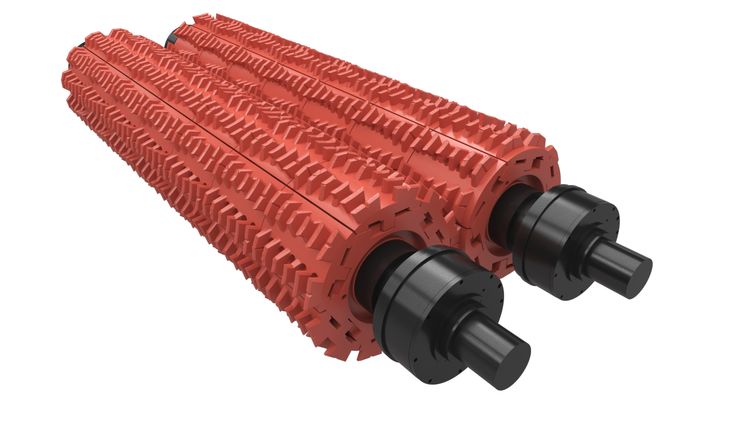

Teeth Roller

The feeding granularity of primary sizers is less than or equal to 1500mm and the discharging granularity is less than 300mm.

The arrangement of crushing teeth shapes and teeth shapes are arranged by special spiral teeth shapes. The crushing teeth are cast from abrasion resistant and impact resistant alloy steel.

Primary Sizer teeth roller has a unique and novel teeth design structure with deep spiral distribution for high productivity. The passing cavities are formed between the two teeth rollers and the side plate body for screening and crushing materials respectively.

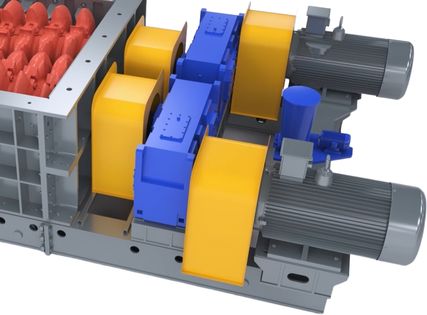

Drive Unit

Two independent drive unit includes, each drive units includes: motor, high-speed end coupling,gear box, low-speed end coupling.

The high-speed end coupling uses hydraulic coupling to connect the motor to the gearbox. The gearbox adopts parallel shaft helical gear structure to meet the requirements of power transmission, speed ratio and torque under extreme load the mineral sizer.

The low-speed end coupling adopts the drum gear coupling which is developed and manufactured by ourselves, and it is used to connect the gearbox to the teeth roller shaft.

The main components of the drive unit will be internationally renowned brands, such as Siemens, SEW, Flender to ensure 24-hour service and availability worldwide.

Synchromesh Gear

The primary mineral sizer is equipped with synchronizing gears at the end of the teeth rolls.

Synchronous gears and roll shafts are connected by the expansion sleeve,which can guarantee the relative stability of the biting position of the crushing teeth on the double rolls, and can force the breaking of large pieces of materials, making the material discharge size uniform.

Housing

Mineral sizer housing is designed as a rigid host frame and the housing is made of cast steel and connected by high strength bolts.

Wear-resistant plates are installed around the inside of the housing, and comb shaped wear plates are installed on both sides of the housing to prevent excessive material from adhering to the crusher teeth rollers.

Lubrication Device

Mineral sizer adopts centralized automatic lubrication system , it can be more oil filling times, oil filling time Settings, reliable to ensure the effective and reliable lubrication of each part.

Automatic control of oil supply speed time, oil supply pressure is large, oil supply speed is fast, the bearing is fully lubricated effectively, so that the core part of the teeth roller bearing to achieve good lubrication, greatly extend the service life of the teeth roller.

FEATURES

Compact Dimensions & Lower Cost

Mineral sizer is compact in size and have a small overall footprint, making it suitable for deployment in situations with limited space.

Compared to other types of crushers with the same capacity,the mineral sizer ensure the smallest size

and lightest weight,which reduces the structural support of the plant and lowers construction costs.

Control Product Size & Minimum Fines

Mineral Sizer has a unique and novel tooth design structure with deep spiral distribution, which the finished product size can be effectively controlled.

The fnished product is uniform in size, with lower oversize and overcrushing than conventional crushers, and the minerals are crushed by low-speed shearing and stretching, resulting in less dust and fnes.

For traditional mining plants, the reduction of fnes ensures the largest percentage of finished material, increasing the economic value of the company.

Handle Complex Materials

Mineral sizer can not only deal with wet or sticky material,but also can deal with dry or hard rock, or deal with sticky material and dry hard rock at the same time.

Automated Operation

Mineral sizer can be fully automated to ensure continuous optimal performance, matched with a PLC control system for remote automatic control and monitoring, overload protection and other functions, providing a safer working environment.

Mineral sizer integrates automatic lubrication system,automatic removal, automatic high temperature alarm for bearings and other functions, which combines the electrical control system to realize remote operation and protect the operator's safety.

Modular design&Easy Maintenance

Mineral sizer can be modularized in design and production, which facilitates equipment installation and routine inspection, maintenance and upkeep.

Modularized components can be replaced quickly and efficiently, reducing downtime for maintenance

and improving the of the mineral sizer.