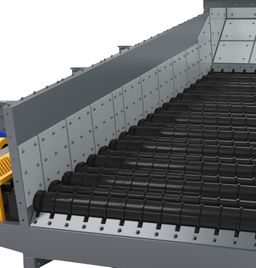

Roller screens, also known as wobble feeders and disc screens, are an efficient screening equipment, the screening area is composed of the main bearing of each roll rotating in the same direction, which can achieve feeding and screening in one operation. Roller screens are very suitable for bulk materials that are difficult to screen, including wet and sticky materials.

The Screen surface of Roller Screen is composed of several parallel arranged screen shafts equipped with shaped screen discs, and the screen shafts are driven by the Drive Device to rotate in the same direction at the same speed, forming a rolling screen surface.

When the material flows on the screen surface, it can form a material flow of equal thickness and with a certain acceleration.

The gap between the screen shaft and the screen disc forms the screen hole, the material less than the screen hole is subjected to its own gravity and the rotating force of the screen shaft, and becomes the material under the screen through the screen holes. Material larger than the screen holes continues to enter along the screen surface under the action of the rotating screen disc, becoming the material on the screen, and finally achieving the classification of the material.

Screen Shaft Assembly

Roller screen disc is cast with wear-resistant manganese chromium alloy steel, which has good wear resistance and can cope with the impact and wear of large materials without any deformation or fracture.

Roller screen disc is designed as a parabolic screen disc. and is rounded to eliminate sharp corners, so that the rotating resistance of the screen is minimized.

Roller screen disc adopts large-curvature and small-curvature arc-shaped structures, thereby completely eliminating industry challenges such as roller shaft jamming during the production process.

The Parabolic shape of the screen disc can maximize the disturbance ability of the roller screen to the material flow and improve the screening rate.

The design of the screen shaft is reasonable and safe, which can effectively avoid the phenomenon of bending and breaking of the roller shaft.

When any group of screen shafts fails, the material can continue to move forward under the push of previous screen shaft, and the screening can operate as usual.

The screen shaft bearing seat is installed on the outside of the screen box side plate for easy disassembly

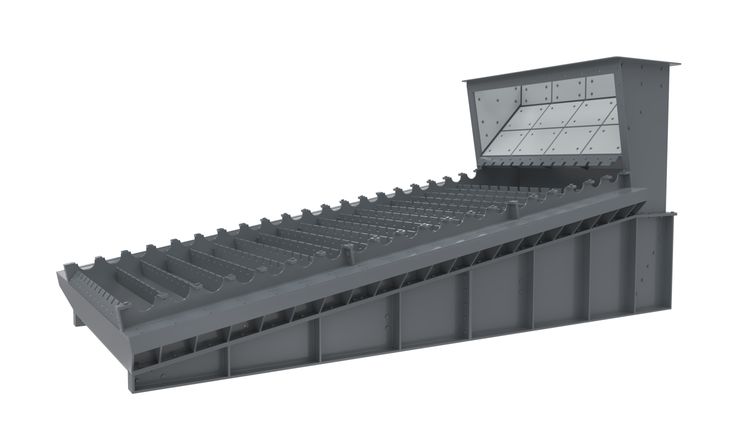

Screen Body

The main body of the roller screen is welded with low-alloy high-strength structural steel. All screen shaft assemblies are fixed to the machine body through connecting bolts.

Wear-resistant lining plates are installed on the side of the machine body to avoid direct contact between materials and the box, greatly extending the service life of the equipment. And the wear-resistant lining plate and the screen box are connected by bolts, which is easy to replace.

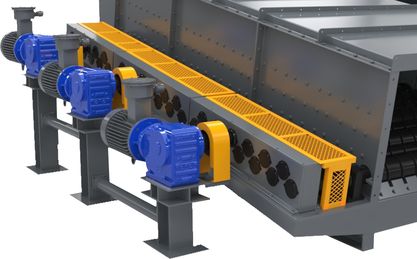

Drive Unit

Roller screen adopts single-axis single-motor drive or multi-axis gearbox combination transmission mode reasonable power configuration to evenly distribute the material in the screen and ensure smooth operation.

The design structure of the drive unit is simple, easy to install and disassemble, and the connected screen shaft is not moved when disassembling.

The drive unit is compact in size, light in weight, long in life and low in maintenance cost

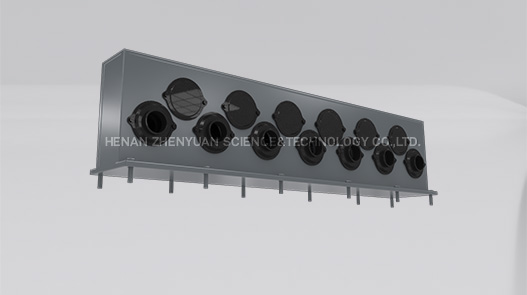

Protective Housing

The protective housing of the roller screen is welded with wear-resistant alloy steel plate, sprayed with anti-rust and anti-corrosion paint, and connected with the hopper and the outlet housing at the front and back.

The protective housing plays a sealing role, and the closed screen box can prevent materials from falling, prevent rain and snow weather from affecting the operation of the equipment, and protect the safety of personnel.

The overall sealing of the screen box can effectively prevent dust pollution, reduce the impact on the environment, and meet the requirements of green construction.

The protective housing is provided with an observation window to facilitate the observation of the operation of the machine.

Lining Plate

The lining plate is made of wear-resistant alloy material,which has a long service life and strong wear resistance,toughness and impact resistance.

The inside of the screen body and the contact surface between the feeding inlet and the material are provided with wear-resistant lining plates, which can protect the screen body and increase the life of

the feeding inlet.

The end of the screen shaft adopts a wear-resistant liner wrapped disc structure, which completely

solves the problem of large blocks stuck on both sides of the screen box and the screen disc, ensuring the normal operation of the equipment.

The lining plate is fixed together with the mother plate by bolts, the replacement is convenient, and reduced maintenance time.

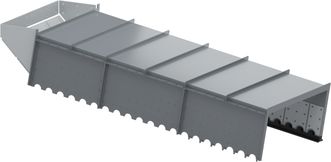

Self-cleaning Device

The self-cleaning device of the roller screen is made of wear-resistant steel and is equipped with a cutting edge, which is inclined to the lower part of the screen shaft.Some fibrous debris and sticky materials attached to the screen will be automatically cleaned off by the cleaning device to solve the blockage of the screen surface.

TECHNICAL COOPERATION AND ACHIEVEMENTS

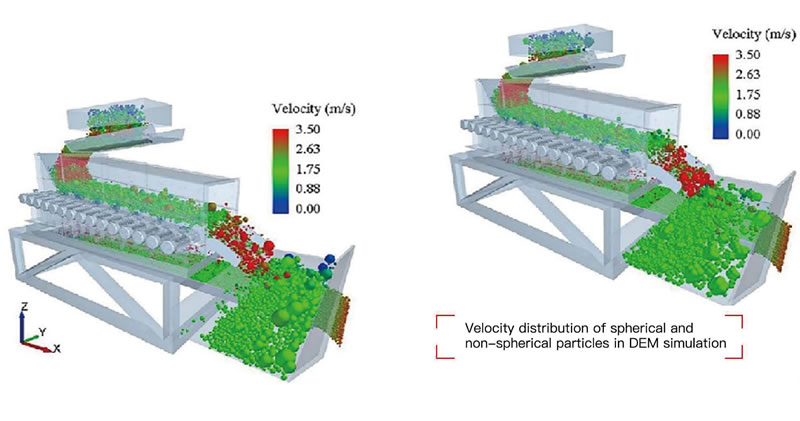

In 2022, in cooperation with China University of Mining and Technology and Xinjiang Tianchi Energy Co., LTD., the virtual screening technology was applied to the screening process simulation and jam analysis of the industrial roller sieve,the significant influencing factors of screening efficiency and movement speed were summarized, and the compression-shear critical crushing analysis method of the stuck material under the occluding state of the roller sieve was proposed. The force characteristics of roller and screen are obtained, and the problem of parameter setting of overload control system is solved effectively.

GZS series large and efficient roller screen has been successfully used in Jining Mining Group, Henan Province Academy of Science Application Physics Institute Limited Company, Xinjiang Tianchi Energy, Qitai County Yindu Construction Engineering Co., LTD. Since the roller screen has been put into operation, the recovery efficiency of lump coal has reached more than 95%, and the environmental protection, safety and health indicators meet the national standards. The equipment has the advantages of stable peration, high reliability, low noise, low bearing temperature, uniform screen surface material distribution, small screen disc wear, and all indicators have reached the advanced level of similar equipment at home and abroad.

Accurate Virtual Screening Test

Screening efficiency is an important index to evaluate the performance of screening equipment.

The speed and residence time of the particles on the screen surface are also important factors affecting the screening process, which not only affects the processing capacity of the screening equipment, but also affects the screening efficiency.

Therefore, in order to study the effect of actual working conditions on the screening performance of the roller screen, a series of parametric studies were carried out on different feed rates, screen shaft rotational speed, screen surface inclination and bonding force, ensure the rationality of selection.

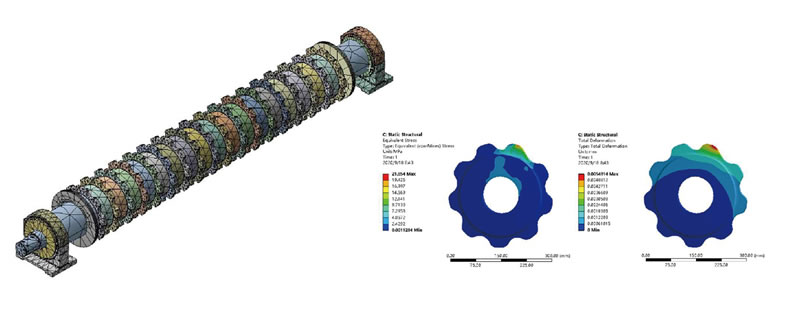

Finite Element Force Analysis On The Screen Shaft

In the static coupling simulation, EDEM mainly provides the stress information of key components during

operation for the finite element analysis of Workbench.

To realize the coupling simulation between EDEM and Workbench, two pieces of software need to be

associated together in Workbench.

The EDEM module is added to Workbench through the interface program, and the EDEM module is associated with the mechanical analysis module in Workbench, and then the force information of the roller obtained from EDEM is imported into the discrete element module in Workbench.

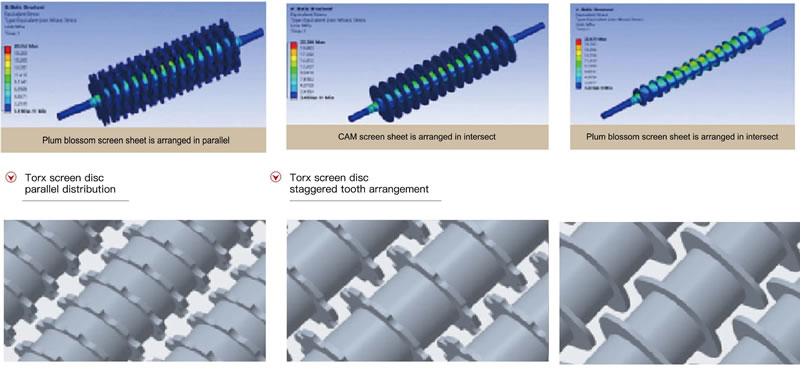

Scientific Screen Disc Selection

On the basis of the existing fnite element checking process, we further simulate the existing screen shaft of other screen disc shapes to explore the influence of screen disc shapes on the stress distribution of the shaft body. In addition to the existing quince-shaped screen disc, we conduct 3D modeling of CAM and sheet shaped roller screen, and carry out finite element check under the same load condition, and select the blade form according to the results.

FEATURES

High Screening Accuracy

High screening accuracy, high efficiency. the handling capacity is 4 times that of the traditional trommel screen of the same volume, the screening efficiency is 1.5 times that of the trommel screen, and the single production capacity can be as high as 1000t/h or so.

Smooth Operation

Adopts single-shaft drive or multi-shafts gearbox combination drive mode, motor, reducer, bearing with high-quality brand,reasonable power configuration and screen surface structure, so that the material load inside the screen evenly distributed to ensure smooth operation.

Run Continuously

The equipment can run continuously, and it can play the functions of conveying, separating, screening and so on under different mines, which can achieve the multi-purpose into one machine.

Modular Assembly

Modular assembly, can be lengthened or shortened according to material conditions, easy maintenance

and structural adjustment.

Environmental Protection

The whole machine adopts completely closed structure, no vibration, effectively avoid dust spillover, low noise, energy saving and environmental protection.

Manual/Automatic Control

The whole machine adopts electrical and mechanical dual protection, with interlock protection function,

can achieve manual control and automatic control.

HANDLING MATERIALS

- Clay

- Mining

- Sand Aggregate

- Solid Waste

- Coal

- Metallurgy

- Argil

- Feeding

- Salt

- Cement

- Bauxite

- Copper Ore

- Electric Power

- Limestone

- Gypsum

- Screening/Sizing

- Aggregates

- Coal Fired Power Plants

- Gold Ore

- Granite

- Ilmenite

- Iron Ore

- Kaolin

- Laterite Ore